Beverage Bot

Beverage Bot is a fully automated lemonade-dispensing system built on the VEX V5 platform. Users can customize sweetness and tartness through the touchscreen interface, and the robot dispenses lemon juice, simple syrup, and water with high precision using peristaltic pumps and a lead-screw driven cup platform. The system uses PID control for smooth motion and accurate fluid metering. The project combines mechanical engineering, software engineering, and controls systems design into a single interactive, educational robot.

Subsystems & Design Iterations

-

Cup Platform

- Moves along two 0.6 m lead screws driven by VEX V5 motors

- Motion profile: Trapezoid-profiled PID to control acceleration and prevent spilling

- Homing using limit switches at both ends

- Stops precisely at Lemon, Sugar, Water, and Delivery stations

- Iteration: Adjusted motor speeds and PID parameters after observing overshoot during early testing

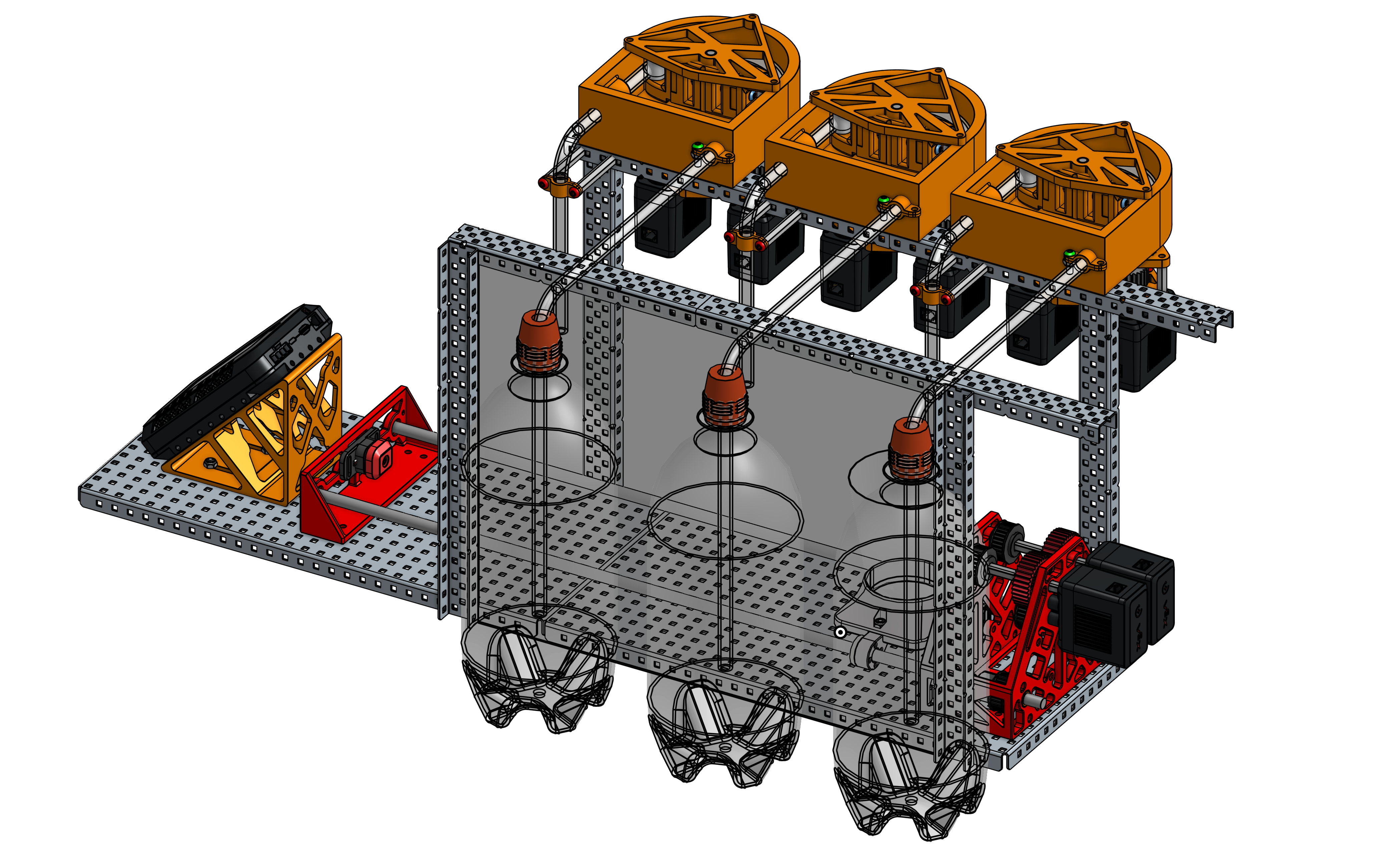

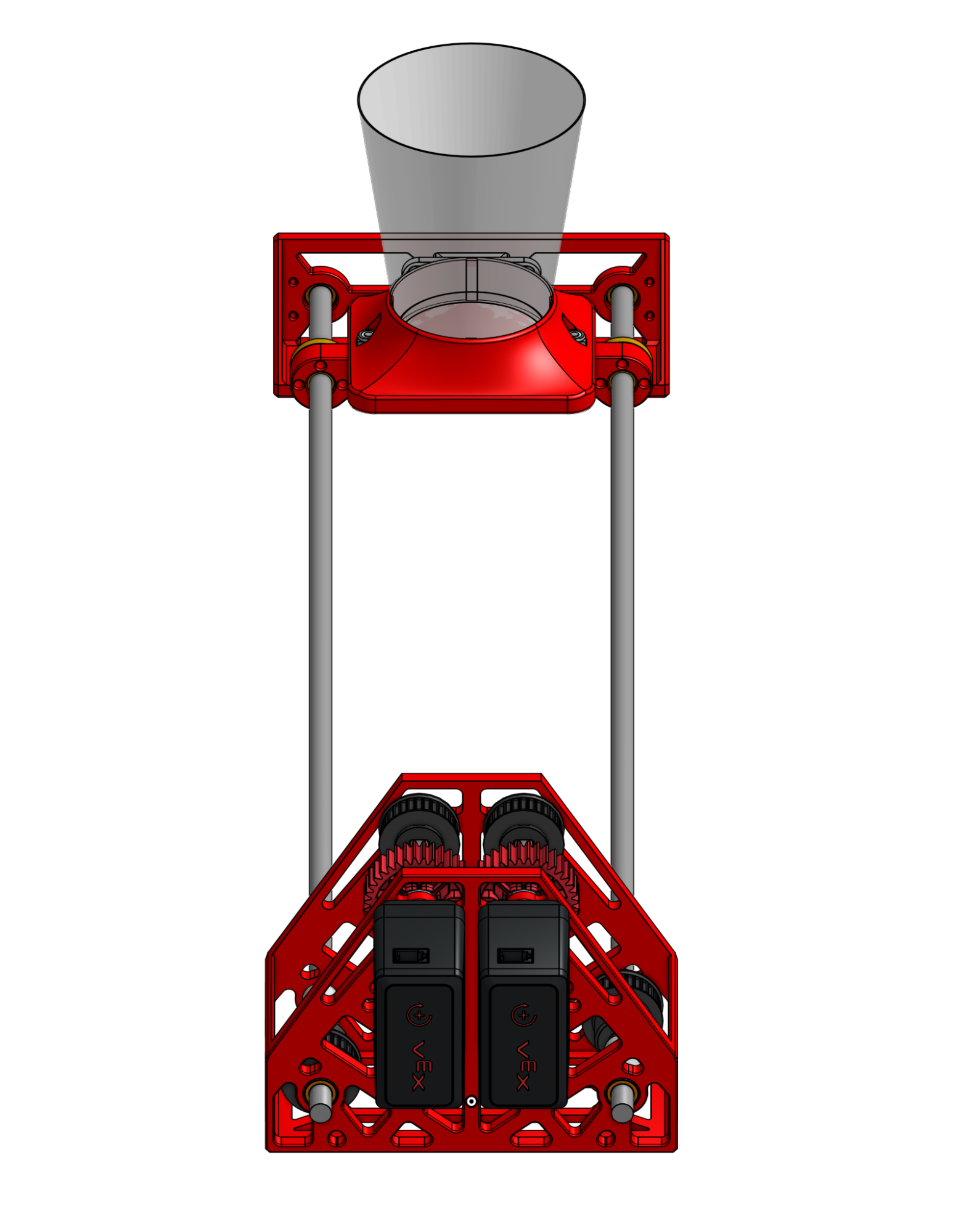

Cup Platform CAD render -

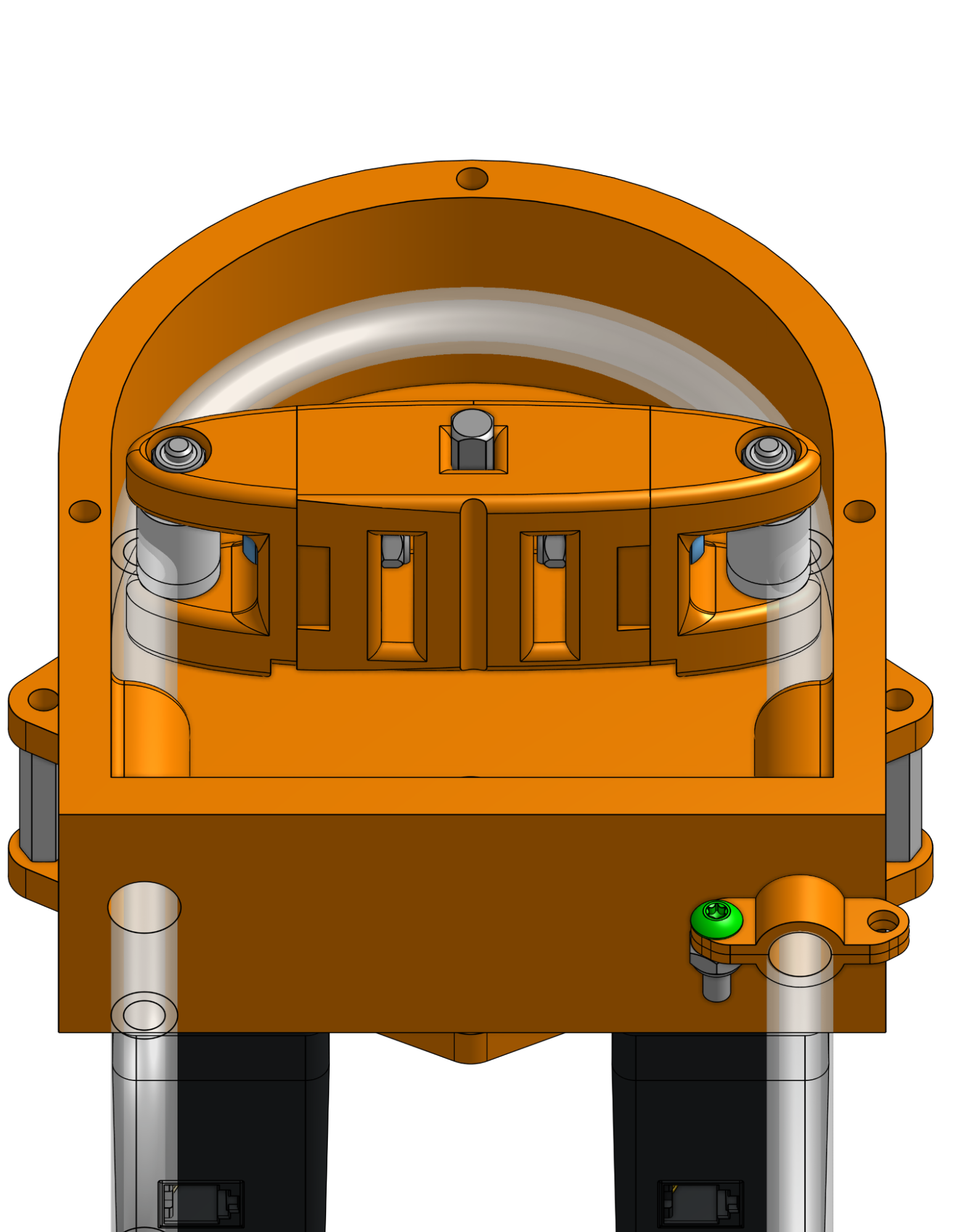

Peristaltic Pumps

- 3D-printed pump housing with silicone tubing

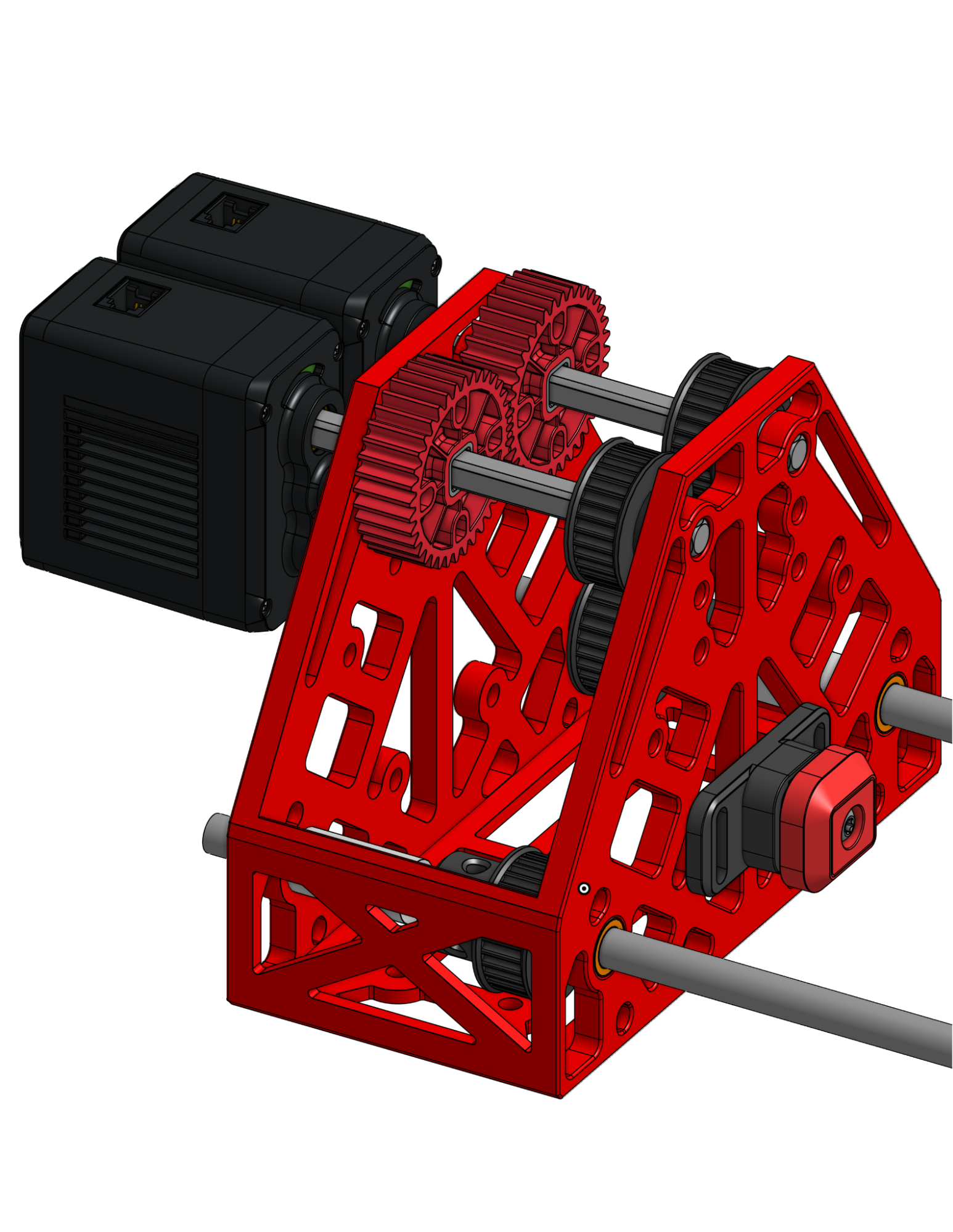

- Driven by two VEX V5 motors per pump to achieve sufficient torque

- Encoder-based PID control ensures precise volume dispensing

- Iteration: Initial single-motor design could not reliably compress tubing; switched to dual-motor with gearbox for optimal torque-speed balance

- Flow rate calibration performed to match desired cup volume; real-world tests required adjustment from theoretical calculations due to tubing compression effects

Peristaltic pump CAD render -

Lemon & Syrup Dispensing

- Delivered via peristaltic pumps to ensure precise liquid volume

- Lemon juice dispensed first, sugar syrup second, water third

- Iteration: Explored solid sugar auger system, but fine sugar jammed the mechanism; switched to simple syrup pumped like other liquids

-

Water Dispensing

- Uses peristaltic pump to add water, assisting with mixing the drink

- PID-controlled flow ensures consistency across cups

- Iteration: Tested different motor speeds to prevent overflow while maintaining adequate mixing turbulence

-

Linear Motion System

- Synchronized dual motors with end stops to move the cup platform linearly

- Motor coordination ensures straight motion; PID controller maintains precise positioning

- Calibration routine detects physical limits and sets start/end positions automatically

- Iteration: Added slowdown factor near end stops to prevent overshoot and physical collisions

Linear Motion System CAD render -

User Interface

- Touchscreen interface on VEX Brain

- Sliders for sweetness (-1 to 1) and tartness (-1 to 1)

- Displays real-time status, errors, and completion messages

- Iteration: Updated UI layout after user testing for easier interaction and feedback visibility

VEX Brain touchscreen UI screenshot -

Software Architecture

- Modular MicroPython code using OOP design

- Classes such as

SetpointManager,PeristalticPump, andLinearMotionSystemencapsulate functionality and simplify debugging - Setpoints allow precise movement between ingredient stations

- Iteration: Adjusted pump control logic and linear motion PID gains based on real-world testing to improve accuracy and reliability

Operational Flow

- Startup and homing of the cup platform via limit switches

- User selects sweetness and tartness on the Brain touchscreen

- System calculates precise volumes for lemon juice, syrup, and water

- Cup moves to Lemon station and receives calculated lemon juice

- Cup moves to Syrup station and receives sugar syrup

- Cup moves to Water station and receives water to complete the mixture

- Final mixed drink delivered at the end station

Technical Documentation Packet

This is the full technical documentation packet I prepared for STEAMFest 2025.

Icons by IONICONS and PAPIRUS icon theme.

This website is based on an MIT-licensed template by codewithsadee.

Copyright (c) 2025 Derek Baier.